Are Hose Clamps Stainless Steel, Corrosion-Resistant, and Rust-Proof?

When selecting hose clamps for industrial, automotive, or household applications, one of the most critical considerations is their resistance to corrosion and rust. Stainless steel hose clamps are widely regarded as the best choice for durability and longevity, but are they truly corrosion-resistant and rust-proof? This article explores the materials, properties, and performance of stainless steel hose clamps in various environments.

1. Understanding Stainless Steel Hose Clamps

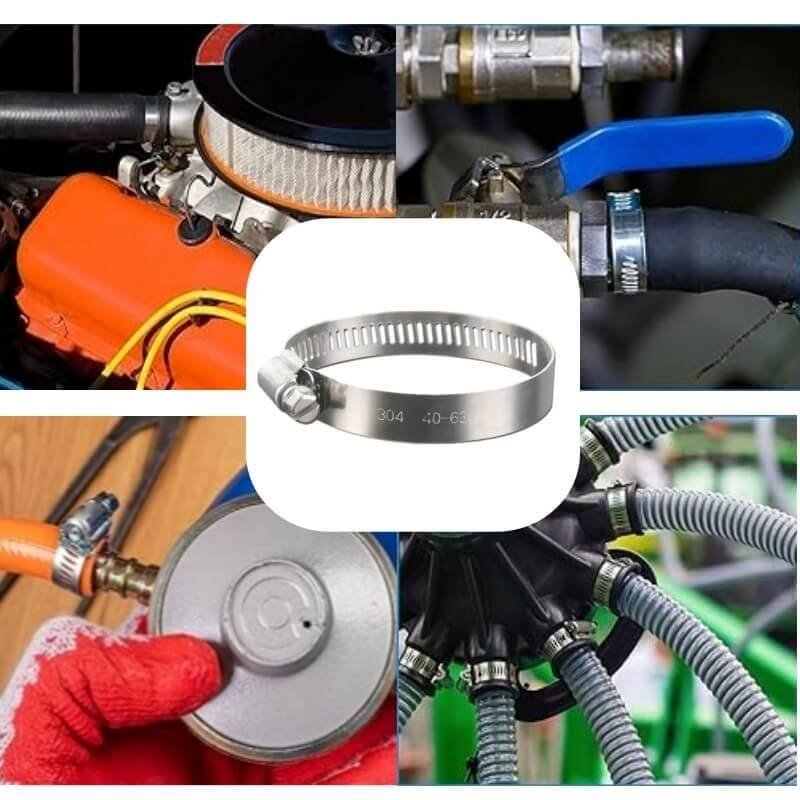

Stainless steel hose clamps are fasteners designed to secure hoses onto fittings, preventing leaks and ensuring a tight seal. They are commonly used in plumbing, automotive, marine, and industrial applications due to their strength and resistance to environmental factors.

Types of Stainless Steel Used in Hose Clamps

Not all stainless steel is the same. The corrosion resistance of a hose clamp depends on its grade:

-

304 Stainless Steel (A2) – Offers good corrosion resistance and is suitable for most environments, including freshwater and mild chemical exposure. However, it is not ideal for highly corrosive conditions like saltwater.

-

316 Stainless Steel (A4) – Contains molybdenum, enhancing its resistance to chlorides and saltwater. This makes it the preferred choice for marine and chemical applications.

-

400 Series Stainless Steel – Less corrosion-resistant than 300 series but offers higher strength. Some budget clamps use this, but they may rust over time.

Hose clamps are adjustable metal bands that secure hoses to fittings

2. Are Stainless Steel Hose Clamps Truly Corrosion-Resistant?

Stainless steel is inherently corrosion-resistant due to its chromium content (at least 10.5%), which forms a passive oxide layer that protects against rust. However, several factors influence its performance:

Factors Affecting Corrosion Resistance

-

Exposure to Chlorides (Saltwater) – 304 stainless steel can suffer from pitting corrosion in marine environments, whereas 316 performs better.

-

High Temperatures – Extreme heat can degrade the protective oxide layer, leading to oxidation.

-

Mechanical Damage – Scratches or improper installation can expose the underlying metal to corrosion.

-

Galvanic Corrosion – When stainless steel comes into contact with dissimilar metals (e.g., aluminum or carbon steel), accelerated corrosion can occur.

Do Stainless Steel Hose Clamps Rust?

While stainless steel is highly resistant to rust, it is not entirely rust-proof. In harsh conditions (e.g., coastal areas, chemical plants, or high humidity), even high-grade stainless steel can develop surface rust over time. Proper material selection (316 over 304) and regular maintenance can mitigate this risk.

3. Comparing Stainless Steel Hose Clamps to Alternatives

Many hose clamps are made from materials other than stainless steel, including:

-

Galvanized Steel – Coated with zinc for rust resistance but less durable than stainless steel.

-

Plastic/Nylon – Lightweight and corrosion-proof but lacks strength for high-pressure applications.

-

Aluminum – Lightweight and corrosion-resistant but weaker than stainless steel.

Stainless steel remains the best all-around choice for balancing strength, durability, and corrosion resistance.

4. How to Choose the Right Hose Clamp for Corrosive Environments

To ensure maximum longevity:

-

Select the Right Grade – Use 316 stainless steel for marine or chemical exposure.

-

Check for Certifications – Look for ISO, ASTM, or DIN standards.

-

Avoid Mixed Metal Contact – Prevent galvanic corrosion by using compatible materials.

-

Inspect Regularly – Check for signs of wear, rust, or loosening.

5. Conclusion: Are Stainless Steel Hose Clamps the Best Choice?

Yes, stainless steel hose clamps are among the most corrosion-resistant and durable options available. While no material is entirely rust-proof, high-quality 304 or 316 stainless steel clamps provide excellent protection in most environments. For extreme conditions, 316 stainless steel is the superior choice.

By understanding the differences in stainless steel grades and environmental factors, you can select the best hose clamps for your needs, ensuring long-lasting performance and reliability.